Water Treatment and Distribution

Home > Water Quality > Water Treatment and Distribution

Over 24 Million Gallons Every Day

The York Water Company supplies over 24 million gallons of water every day to over 81,000 residential, commercial, and industrial customers. Over 214,000 people use our water in 58 Pennsylvania municipalities in Adams, Franklin, Lancaster and York counties.

Learn how we treat and distribute our drinking water.

-

Where does your water come from?

York Water maintains multiple water treatment and distribution systems.

Each system has its own source, treatment, and distribution process.

-

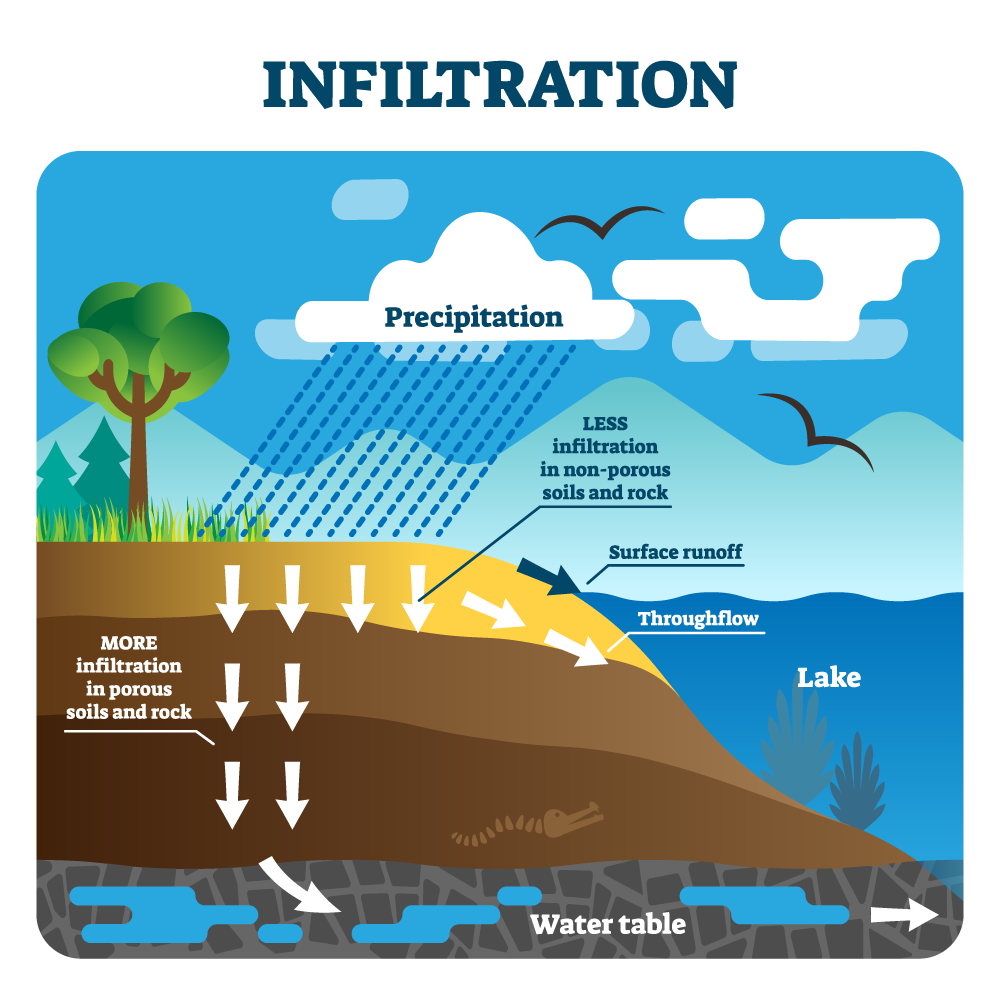

Groundwater

Groundwater, including wells, is the source of many of our water systems. These systems in Adams and Lancaster Counties have groundwater sources:

- Amblebrook

- Conewago Industrial Park

- Carroll Valley

- Country View Manor

- Eastern Cumberland

- Houston Run

- Western Cumberland

-

Water Treatment: Ground Water Sources

The soils, rocks, and sand that ground water flows through naturally filter it. We pump water from groundwater wells and treat it with a disinfectant. Our treatments are based on federal and state drinking water standards.

After we treat the water, we distribute it to the homes in our water systems.

-

Surface Water

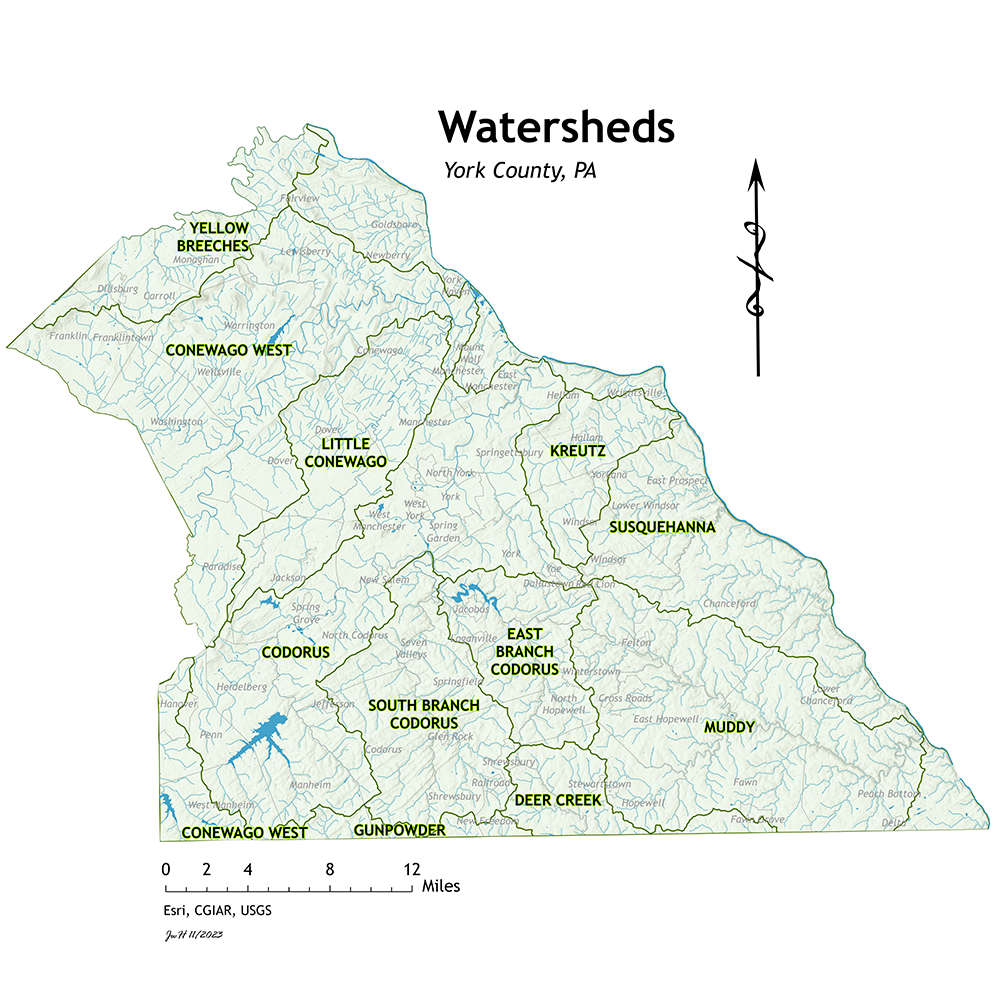

Both the York system and the Franklin County water system are fed by surface water that comes from watersheds.

This map shows bodies of water and watersheds in York County. The South Branch Codorus and East Branch Codorus watersheds are the sources of drinking water in our York water system.

-

Water Treatment: Surface Water Sources

Drinking water source from surface water goes through more steps than sources from groundwater. It starts with impounding water in reservoirs.

York’s Lake Redman (foreground) and Lake Williams (background) are pictured here.

-

The Franklin County Reservoir

Letterkenny’s water source is the Conodoguinet Creek watershed that flows into the Letterkenny Reservoir. From the reservoir, water flows by gravity to the water treatment plant.

Pictured is the Franklin County Reservoir.

-

York’s Lake Redman and Lake Williams

Lake Redman and Lake Williams are The York Water Company’s York County reservoirs. The East Branch Codorus Creek flows into Lake Redman. Next, the water from Lake Redman flows through a spillway into Lake Williams.

Spillways release water from a reservoir in a controlled manner.

-

The Lake Williams Dam

From Lake Williams, water flows over the Lake Williams Dam into the South Branch Codorus Creek, York’s second surface water source.

-

Lake Redman Pumping Station

When needed, the Lake Redman Pumping Station can pump water from Lake Redman to our treatment plant.

-

Brillhart Pumping Station

Lake Williams flows into the South Branch Codorus Creek. The creek carries water to Brillhart Pumping Station. From there, we pump the water to our York treatment plant.

Pictured is Brillhart Pumping Station in its early days. It was built in 1896. Back then, a steam engine powered by coal pumped water to the the water treatment plant.

-

Conservation Practices

Not all the water that flows into the South Branch Codorus Creek makes it into our drinking water.

Countless plants and animals depend on the creek. We send at least 8 million gallons of water per day past Brillhart Pumping Station to support plants and wildlife downstream.

Learn more about how we protect our watershed here. (The link will open in a new tab.)

-

A Backup Water Supply

In 2004, York Water built the Susquehanna River Pumping Station. Its purpose is to supplement the York water system during a drought. It can supply York with 12 million gallons of water per day. We used the pumping station in September 2023 for the first time since it was built.

Watch a short video about why the pumping station was used here. (The link will open in a new tab.)

-

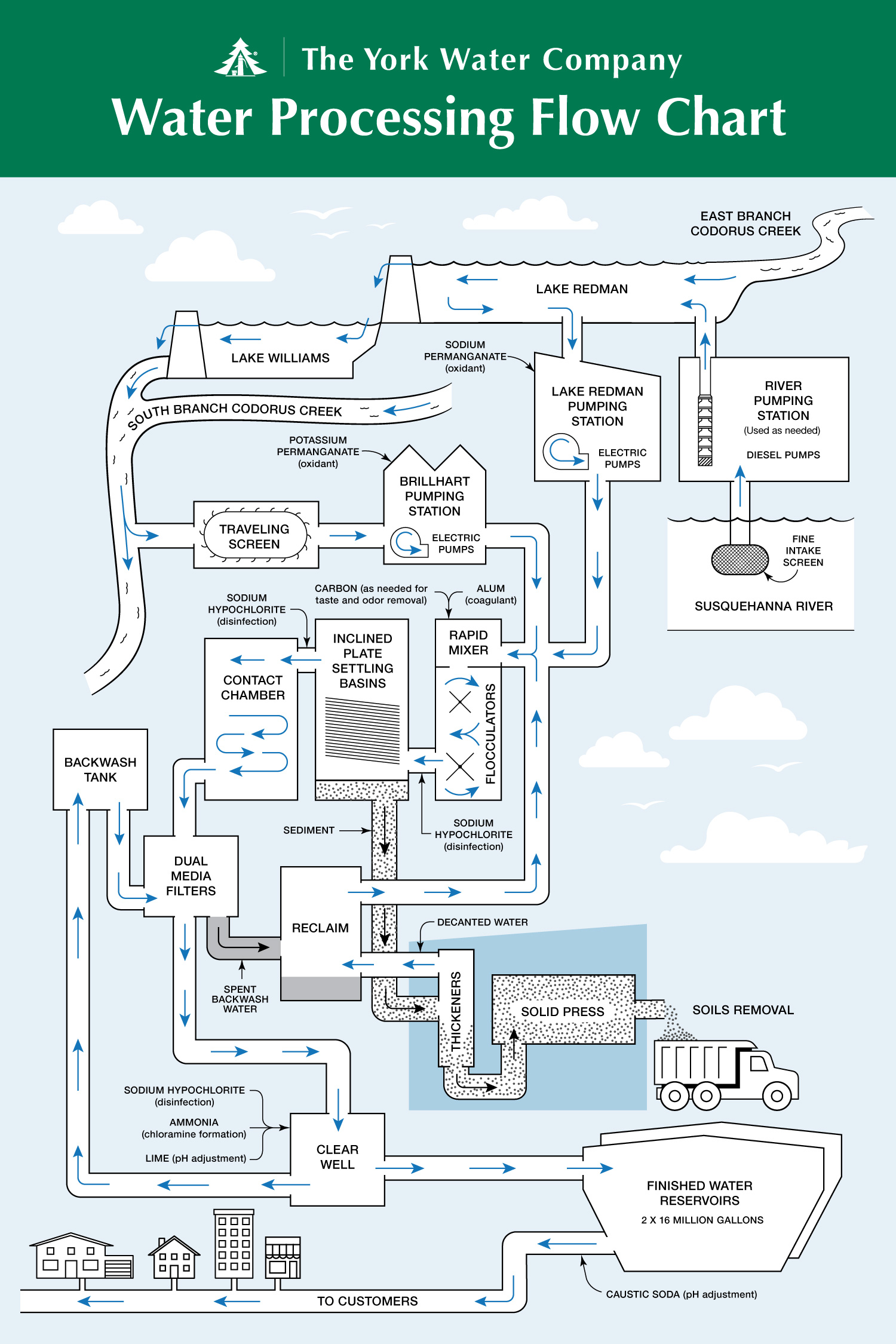

The Treatment Process Begins

We begin the water treatment process at our pumping stations. We add a pre-oxidant to the water. This causes materials that have dissolved in the water, like iron and manganese, to turn into solid particles. When those materials are solid, they can be removed.

Want to view the process more closely?

-

Monitoring Water

We monitor water electronically at our pumping stations. In real time, monitors send information about the water at the pumping station to our treatment plant control center.

It can take 1 to 2 hours for water to travel to the treatment plant. When it arrives, we are ready to treat it.

-

Water Treatment: Carbon

When water in the York and Letterkenny systems reaches a treatment plant, it is first treated in a rapid mixer. If the water has a poor taste or odor, we add carbon to it.

Pictured here is our Water Treatment Plant in York. On the outside, is stately brick building. Inside, the building houses pumps, filters, and our control center.

-

What causes water to have an earthy taste or odor?

As water flows through streams, it moves through dirt and rocks in stream beds. The dirt and rocks are full of minerals that impart earthy flavors into the water.

When water levels are low (for example, during a drought), more water flows through stream beds and collects mineral flavors. When water levels are normal, less water touches the dirt and rocks in stream beds, and the mineral flavors are diluted.

-

Water Treatment: Coagulation

In the rapid mixer, we add alum to the water. Alum is a coagulant. It neutralizes the charge of particles that have dissolved in the water. When the particles are neutralized, they floc, or clump together.

The water samples in this image are from the same source. The sample on the left has been treated with alum, and the sample on the right has not.

-

Water Treatment: Flocculation

After alum is added, water enters the flocculators. The flocculators mix the water and the floc particles in a series of chambers. Each chamber causes the floc particles to clump together even more. In the last step of flocculation, we add a disinfectant to the water.

Pictured is water in the flocculators. It tends to look dirty because the floc particles are getting bigger and have not been given a chance to settle. We take care of that in the next step.

-

Water Treatment: Sedimentation

Water moves from the flocculators to the settling basin in the sedimentation step shown here. In the settling basin, the floc particles, which we now call sediment, sink onto a series of plates.

The plates are inclined, which means they’re set at an angle. Sediment slides down the incline to the bottom of the settling basin, and it is separated from the water.

-

Water Treatment: Filtration

After sedimentation, we filter the water with dual-media filters. They are made of two layers: sand and anthracite. Those layers, or filters, remove unwanted particles from the water.

This image shows water at the beginning of a filter wash.

-

Water Treatment: Filtration

The filters are especially good at removing pathogens that are resistant to chlorine from the water. They also remove remaining particulate matter.

This image shows water approaching the end of the wash. We have filtered out the particles that caused it to be cloudy and some particles that you cannot see.

-

Water Treatment: Disinfection

Next water flows to a clear well. In the clear well, we disinfect the water again. We also adjust the pH. Proper pH improves the taste of our water, reduces corrosion in pipes, and helps disinfectants do their job.

Finished water moves into covered storage basins.

-

Water Treatment: Sampling and Testing

Operators work 24 hours a day, 7 days a week to monitor and treat water at our water treatment plants.

In this image, water just after the dual media filter runs clear from the tap on the left. The brown water coming from the tap on the right is water just before it enters the rapid mixers, step one at the treatment plant.

-

From the Treatment Plant to Your Tap

As water exits the storage basins at our treatment plants, we adjust the pH one more time. In York, the water flows by gravity into water mains. As water moves further away from treatment plants, pumping stations may aid the flow of water.

From the water mains, water flows to our customers’ taps so they can enjoy high-quality drinking water!